ROCKWELL HARDNESS TESTER

The Rockwell hardness test, standardized by ISO 6508 and ASTM E18, is the most widely used method globally for determining material hardness. Suitable for most metals and some plastics, it measures the permanent indentation depth created by a specific force on a designated indenter. Requiring minimal sample preparation, the Rockwell test is known for its speed and ease of use, providing direct hardness readings immediately after indentation.

INNOVATEST offers a comprehensive range of dedicated Rockwell hardness testing instruments employing Load Cell Closed Loop technology. These instruments are subject to thorough development, design, and endurance testing protocols within our dedicated facilities.

INNOVATEST offers a comprehensive range of dedicated Rockwell hardness testing instruments employing Load Cell Closed Loop technology. These instruments are subject to thorough development, design, and endurance testing protocols within our dedicated facilities.

Rockwell Hardness Testers Product Lineup:

- FENIX Series: Achieve precise hardness measurements (Rockwell, Superficial Rockwell, and Brinell) with testers ranging from manual to advanced closed-loop force feedback systems.

- HAWK Series: Featuring a unique protruding nose design, these testers are ideally suited for both internal and external surface testing applications.

- GEMINI Series: Equipped with an all-linear force application system, this series eliminates tolerance errors and facilitates advanced automation capabilities.

- VERZUS Series: This series is engineered for maximum rigidity and accuracy, incorporating a motorized spindle and a suite of advanced features.

Manufacturer’s website: http://www.innovatest-europe.com

Rockwell Hardness Tester Products

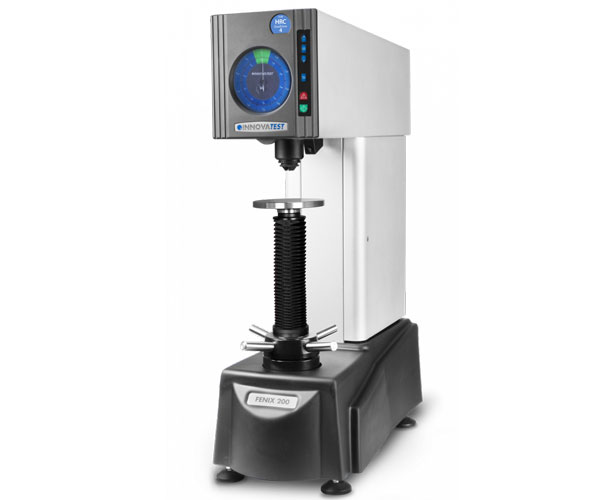

FENIX

FENIX 200AR

10kgf – 150kgf

Rockwell scales only.

Manual, dead-weight.

Analogue reading.

Manual, dead-weight.

Analogue reading.

FENIX 200ACL

10kgf – 187.5kgf

Rockwell & Brinell scales Load Cell, Closed Loop system.

Analogue reading, digital settings.

Analogue reading, digital settings.

FENIX 200DCL

10kgf – 187.5kgf

Rockwell & Brinell scales Load Cell, Closed Loop system.

Full color digital touchscreen.

Full color digital touchscreen.

FENIX 300RS

1kgf – 250kgf

Rockwell, Superficial Rockwell & Brinell Load Cell, Closed Loop system.

Direct depth measurement with I-TOUCH™ system.

Direct depth measurement with I-TOUCH™ system.

FENIX 300RS-IMP

10kgf – 150kgf

Rockwell, Superficial Rockwell, Brinell Load Cell, Closed Loop system.

Direct depth measurement with IMPRESSIONS™ LT system.

Direct depth measurement with IMPRESSIONS™ LT system.

HAWK

HAWK 250RS

1kgf – 187.5kgf

(Superficial) Rockwell, Brinell, Vickers Fully automatic, Load cell, closed loop.

Direct depth measurement with I-TOUCH™ system.

Direct depth measurement with I-TOUCH™ system.

HAWK 400RS

1kgf – 187.5kgf

(Superficial) Rockwell, Brinell, Vickers Fully automatic, Load cell, closed loop.

Direct depth measurement with I-TOUCH™ system.

400mm working height.

Direct depth measurement with I-TOUCH™ system.

400mm working height.

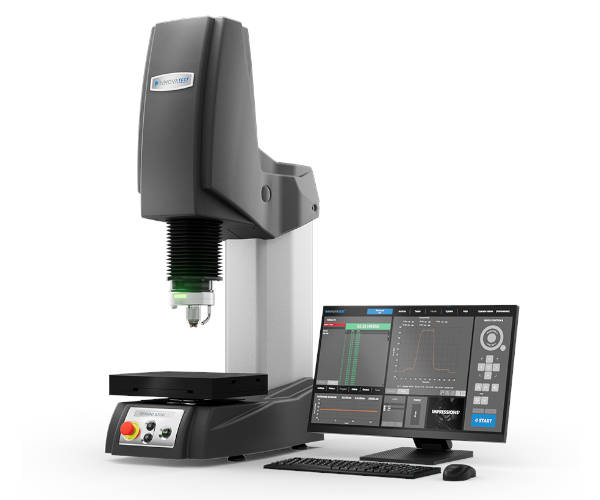

HAWK 400RS-IMP

1kgf – 187.5kgf

(Superficial) Rockwell, Brinell, Vickers Fully automatic, Load cell, closed loop.

Direct depth measurement with IMPRESSIONS™ MT system.

400mm working height.

Optional motorized spindle.

Direct depth measurement with IMPRESSIONS™ MT system.

400mm working height.

Optional motorized spindle.

HAWK 651RS

3kgf – 150kgf

(Superficial) Rockwell Fully automatic, Load cell, closed loop.

Direct depth measurement with I-TOUCH™ system.

650mm working height.

Direct depth measurement with I-TOUCH™ system.

650mm working height.

HAWK 652RS-IMP

1kgf – 187.5kgf

(Superficial) Rockwell, Brinell, Vickers Fully automatic, Load cell, closed loop.

Direct depth measurement with IMPRESSIONS™ system.

650mm working height.

Direct depth measurement with IMPRESSIONS™ system.

650mm working height.

GEMINI

GEMINI 6100G2

1kgf – 250kgf

Rockwell, Superficial Rockwell & Brinell

Direct depth measurement

Descending test head

with I-TOUCH™ system

Small and large model available

GEMINI 6200G2

1kgf – 250kgf

Rockwell, Superficial Rockwell & Brinell

Direct depth measurement

Descending test head

with IMPRESSIONS™ system

Small and large model available

VERZUS

VERZUS 720RS

1kgf – 250kgf

Rockwell, Superficial Rockwell & Brinell Load cell, Closed Loop system.

300mm working height.

Direct depth measurement.

IMPRESSIONS™ LT & Integrated PC.

Soft keys for harsh environment.

300mm working height.

Direct depth measurement.

IMPRESSIONS™ LT & Integrated PC.

Soft keys for harsh environment.