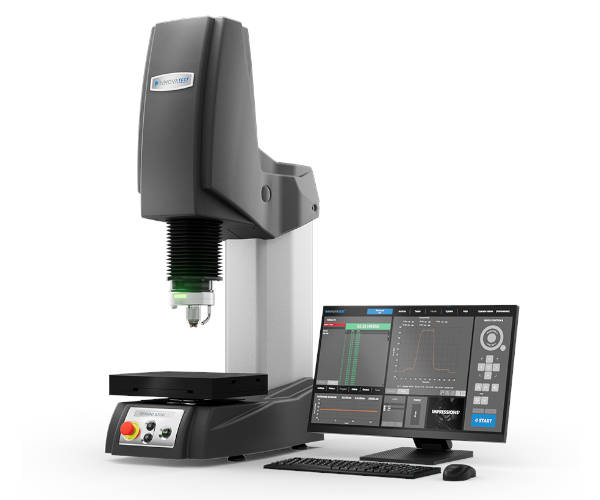

INNOVATEST GEMINI 6200G2

Rockwell Hardness Tester

Looking for the most advanced Rockwell hardness tester on the market? The INNOVATEST GEMINI 6200G2 sets a new standard for modern hardness testing. Built for maximum accuracy, automation, and versatility, this next-generation system is perfect for high-demand industries in Singapore.

The GEMINI 6200G2’s revolutionary all-linear force application system—featuring a descending test head and fixed workpiece position—eliminates tolerance errors, ensuring every test delivers repeatable, highly accurate results.

The GEMINI 6200G2’s revolutionary all-linear force application system—featuring a descending test head and fixed workpiece position—eliminates tolerance errors, ensuring every test delivers repeatable, highly accurate results.

Key Features of INNOVATEST GEMINI 6200G2

- Advanced All-Linear Force System: By using a descending test head with a fixed workpiece, the GEMINI 6200G2 provides the highest accuracy by completely eliminating tolerance errors in depth measurement.

- High-Performance Testing Technology: This system features a load cell, force feedback, and a closed-loop system for precise force control. It is fully automated with stepper or servo motor drivers for high-throughput testing.

- IMPRESSIONS™ Advanced Hardness Software: Take full control of your testing process with this powerful software. It manages core functions and accessories like Jominy and motorized stages, while offering robust reporting, analysis, and data integration capabilities.

- Flexible Configurations: Choose the perfect fit for your needs:

- Short version (S150): A compact, high-precision solution ideal for laboratories.

- Tall version (T300): Designed for workshops and handling larger industrial parts.

- Large Integrated Test Table: The spacious test table can accommodate a wide variety of samples and supports a range of accessories, including V-anvils and motorized stages.

REQUEST A QUOTE / ENQUIRY FORM

SPECIFICATIONS

APPLICATIONS

VIDEO

SPECIFICATIONS

| Scales | Rockwell, Superficial Rockwell, Brinell, HVD/HBD, Plastics & Carbon |

| Test Forces | 1 kgf – 250 kgf (load cell, closed loop system) |

| Load Application System | Fully automatic, load cell, closed loop, force feedback |

| Overview Camera | 13 MP stage overview camera, variable field of view |

| Display | 24″ landscape mode capacitive touchscreen |

| Indenters | IRIS™ intelligent indenter system |

| Control | Integrated controller, i7 processor, Dual MSSD RAID storage or external PC |

| Laser | Cross laser positioning system |

| Illumination | Multi-color LED machine status indicator |

| Z-Axis | Descending test head, collision detection, CNC motorized (T model), ball bearing spindle, fast up/down & start buttons |

| Stages | Manual or motorized |

| Workpiece Height | Short version (S): 150 mm, Tall version (T): 300 mm |

| Output | XML, CSV, Q-DAS certified (optional) |

| Software Functions | Wide range of software features, plug-ins, add-ons, Q-DAS certified |

APPLICATIONS

The INNOVATEST GEMINI 6200G2 is a versatile and precise hardness testing machine designed to meet the rigorous demands of various industries and applications, including:

- Aerospace – Aircraft engine components and structural parts.

- Automotive – Testing of vehicle parts and assemblies.

- Production Lines – Inline quality control and process monitoring.

- General QA & Material Certification – Reliable hardness testing across metals and alloys.

- Research Laboratories – High-standard R&D applications requiring ultimate accuracy.

VIDEO

ROCKWELL HARDNESS TESTER

ROCKWELL HARDNESS TESTER

Menu